Electrolyte and Electrode Core Material Price Hikes Push Up Energy Storage Cell Costs

Against the backdrop of the accelerating expansion of the global energy storage industry, price fluctuations of lithium hexafluorophosphate and lithium iron phosphate have emerged as the core factors driving up energy storage cell costs.

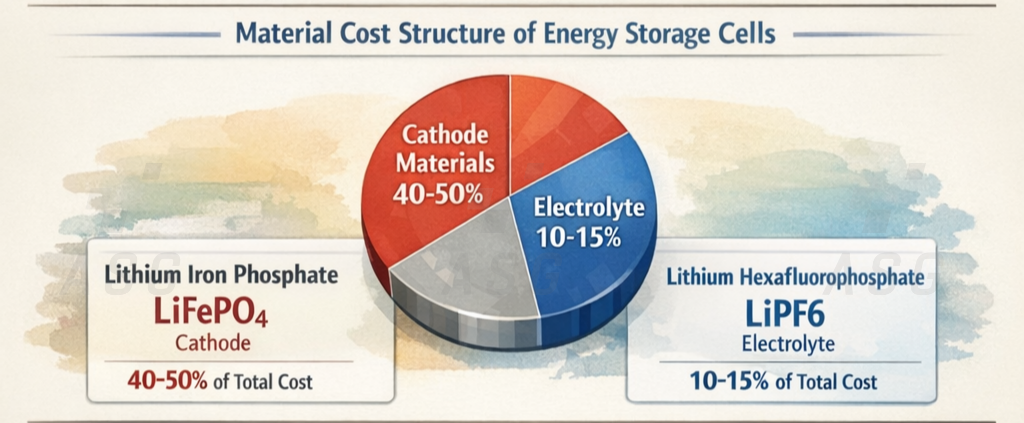

I. Material Cost Structure of Energy Storage Cells

Material costs account for 60%-70% of the total production cost of energy storage cells, forming the core determinant of final cell pricing. Among the components, cathode materials take up 40%-50%, with lithium iron phosphate—the mainstream cathode material—exerting a direct impact on cell cost fundamentals. Electrolyte costs make up 10%-15% of the total; lithium hexafluorophosphate, as the key raw material for electrolytes, accounts for 40%-50% of electrolyte costs. Although it only contributes about 7% to the overall cell cost, its high price elasticity leads to a prominent influence on cost fluctuations.

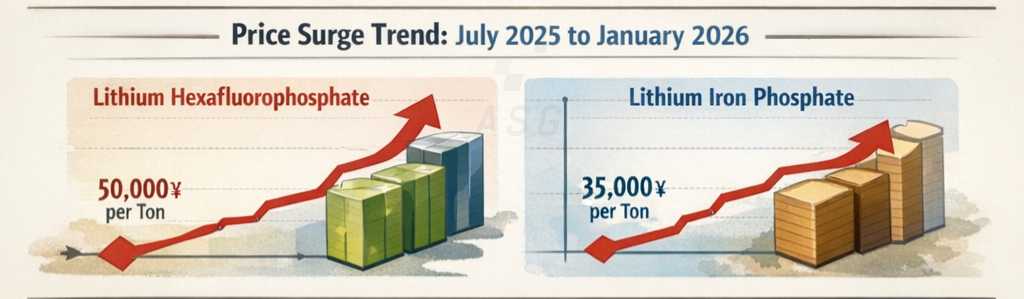

II. Price Surge Trend of Core Materials from July 2025 to January 2026

During this period, prices of the two materials skyrocketed, driven primarily by supply-demand mismatch.

- Lithium Hexafluorophosphate: The price hit a historic low of below 50,000 yuan per ton in July 2025. Subsequently, fueled by surging demand and shrinking production capacity, the price soared continuously, stabilizing at 170,000-180,000 yuan per ton in January 2026, representing a 260% increase.

- Lithium Iron Phosphate: The price remained stable before October 2025, with an average of 35,000 yuan per ton. In December, manufacturers collectively raised prices: the price of energy storage-grade products rose above 32,000 yuan per ton, while that of power-grade products climbed to 45,100 yuan per ton, jumping by over 15% from mid to late December.

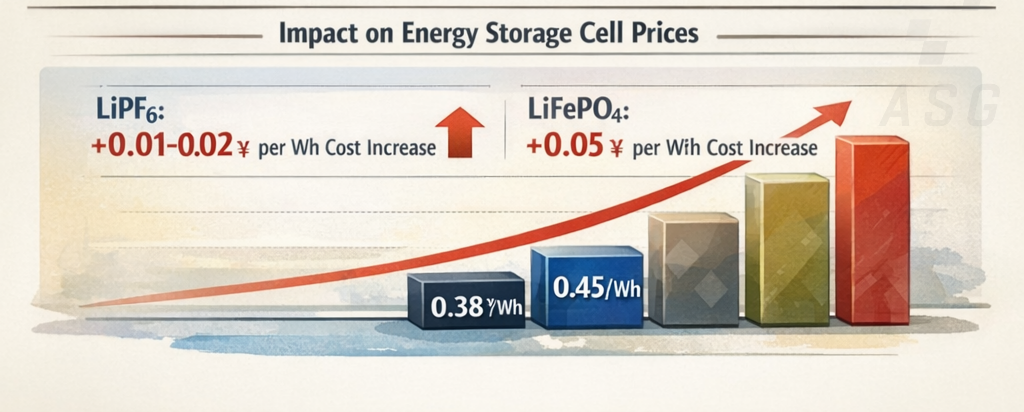

III. Impact of Material Price Hikes on Energy Storage Cell Prices

The price surge of core materials has triggered a clear cost pass-through effect.For every 10,000 yuan per ton increase in lithium hexafluorophosphate price, the cost of energy storage cells rises by approximately 0.01-0.02 yuan per Wh. For every 10,000 yuan per ton increase in lithium iron phosphate price, cell cost increases by around 0.05 yuan per Wh. By January 2026, the price hikes of the two materials have driven a cumulative increase of 0.18-0.28 yuan per Wh in the unit cost of energy storage cells.In terms of terminal prices, the procurement price of energy storage cells rose from 0.38 yuan per Wh to 0.45 yuan per Wh in Q3 2025, with quotes for mainstream specifications climbing further in December. Cell prices are projected to exceed the 0.48-0.50 yuan per Wh range in 2026. At the enterprise level, small and medium-sized manufacturers have seen their costs surge by over 20%, with some projects’ internal rates of return falling below 5%. Leading enterprises, despite hedging risks through long-term supply agreements, still have to raise product quotes.